Alkaline water electrolysis hydrogen production device

Key words:

Alkaline water electrolysis hydrogen production device

Classification:

- Product Description

-

Technology of Hydrogen Production by Alkaline Water Electrolysis

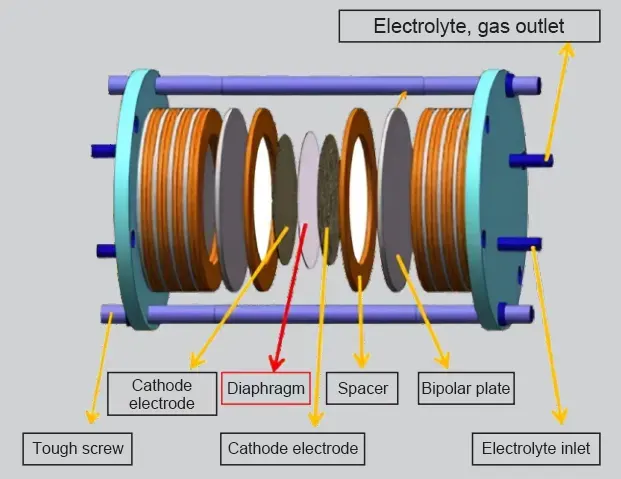

The alkaline water electrolysis cell for hydrogen production is composed of plates, electrolytes, electrodes, catalysts, diaphragms and other parts. The electrolyte of the alkaline electrolyzed water is a 30% by mass (wt%) KOH or NaOH solution. In the electrolytic state, the cathode water generates hydrogen and hydroxide ions, hydroxide ions pass through the diaphragm, and the anode hydroxide loses electrons to generate oxygen. At the present stage, ammonia production from alkaline water electrolysis is a hydrogen production technology with low cost, the most mature technology and the highest degree of industrialization.

■Technical features

Ultra pure hydrogen:The purity of hydrogen produced by the equipment is as high as 99.999, the dew point can reach -65°C, the load adaptability is strong, and the operating pressure and output are continuously adjustable below the rated value. The system monitors the purity of hydrogen production online in real time, which can extend the service life of the equipment and greatly reduce the maintenance and replacement costs.

Proven reliability: The electrolytic cell body is a bipolar filter-pressing plate and frame structure, using special sealing structure and materials, and no leakage for long-term operation.

Gas production on demand:The maximum gas production is different according to the model, and the larger hydrogen production can be customized.

Easy installation: Each set of hydrogen production system has been assembled before leaving the factory, and adopts an integrated frame structure, which is convenient for transportation and simple and fast installation on site.

Strict process control:The design, material selection and processing of each set of equipment are strictly controlled.

■ Main performance indicators

Electrolyzer design life:Fault-free continuous operation shall not be less than 80000 hours (except for wearing parts)

Hydrogen content in oxygen at oxygen outlet:Less than 1.5 percent by volume

Hydrogen dew point at system outlet:≤-65 °C

hydrogen export dust particles:≤ 1.0u

Normal automatic operation of hydrogen and oxygen liquid level difference:<20mm (water column)

■ Electrolytic cell structure diagram

■ Some products

Leave A Message

Methanol cracking hydrogen production unit

Methanol cracking-pressure swing adsorption hydrogen production technology is a kind of methanol, water as raw materials, at a certain temperature and pressure by the catalyst into a mixed gas into a certain temperature and pressure by the catalyst cracking into a hydrogen-containing mixed gas, and then through the pressure swing adsorption purification of hydrogen technology.

Natural gas hydrogen production unit

The technology uses natural gas to undergo a chemical reaction with water vapor in a special reformer filled with a catalyst after pressurized desulfurization to generate a converted gas containing hydrogen, carbon dioxide and carbon monoxide. After part of the heat is recovered by the waste pot, CO in the converted gas is converted into H?, and the converted gas is purified by pressure swing adsorption (PSA) after cooling and condensing gas-liquid sharing.

Pressure swing adsorption hydrogen extraction device

After the mixed gas containing hydrogen (H₂) enters the adsorption tower of pressure swing adsorption (PSA) device, because the adsorption capacity of the adsorbent in the adsorption bed for each component in the gas mixture varies with the pressure change, the impurities in the feed gas are adsorbed during pressurization, and the components (hydrogen) that are not easily adsorbed are output as products from the outlet end of the adsorption bed. During decompression, the adsorbed impurities are desorbed and the adsorbent is regenerated at the same time, at least four adsorbent bed cycles are used to operate to achieve a continuous output of product hydrogen.

VPSA pressure swing adsorption oxygen plant

Multi-tower combined VPSA pressure swing adsorption oxygen production technology is a new process with low energy consumption, low noise and low maintenance cost. It has been accepted by the first set of devices in Zhejiang Province and is widely used in non-ferrous smelting, glass smelting, iron and steel smelting, chemical industry, paper making and other industries.

SAF Coolest v1.3.1.2 设置面板 QBJSD-ZZZH-FXSVE-DSV

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page