22000nm ³/h VPSA pressure swing adsorption oxygen generator

Key words:

Classification:

- Product Description

-

Multi-tower combined VPSA pressure swing adsorption oxygen production technology

Multi-tower combined VPSA pressure swing adsorption oxygen production technology is a new process with low energy consumption, low noise and low maintenance cost. It has been accepted by the first set of devices in Zhejiang Province and is widely used in non-ferrous smelting, glass smelting, iron and steel smelting, chemical industry, paper making and other industries.

■Technical features

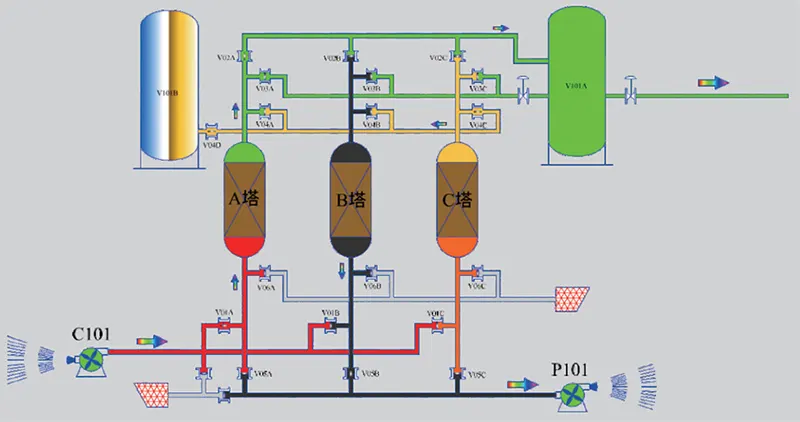

The use of three-tower continuous oxygen production process, the selection of new oxygen-making special molecular sieve and new oxygen program control valve, to achieve efficient and stable oxygen production, is a low energy consumption, low noise, low maintenance costs and other new oxygen production process. Electricity consumption for oxygen production is less than 0.28Kwh/Nm3_O2The oxygen recovery rate is as high as 67%.

The oxygen purity is adjustable within 25-95%, and the output is adjustable within the range of 50%-110 of the rated production capacity. This type of device has the advantages of short process, strong practicability, high degree of automation and convenient opening and parking.

■ Flow diagram

Leave A Message

35000nm ³/h methanol cracking hydrogen production unit

Methanol cracking-pressure swing adsorption hydrogen production technology is a kind of methanol, water as raw materials, at a certain temperature and pressure by the catalyst into a mixed gas into a certain temperature and pressure by the catalyst cracking into a hydrogen-containing mixed gas, and then through the pressure swing adsorption purification of hydrogen technology.

12500nm ³/h natural gas hydrogen production unit

The technology uses natural gas to undergo a chemical reaction with water vapor in a special reformer filled with a catalyst after pressurized desulfurization to generate a converted gas containing hydrogen, carbon dioxide and carbon monoxide. After part of the heat is recovered by the waste pot, CO in the converted gas is converted into H?, and the converted gas is purified by pressure swing adsorption (PSA) after cooling and condensing gas-liquid sharing.

60000nm ³/h pressure swing adsorption hydrogen extraction device

After the mixed gas containing hydrogen (H₂) enters the adsorption tower of pressure swing adsorption (PSA) device, because the adsorption capacity of the adsorbent in the adsorption bed for each component in the gas mixture varies with the pressure change, the impurities in the feed gas are adsorbed during pressurization, and the components (hydrogen) that are not easily adsorbed are output as products from the outlet end of the adsorption bed. During decompression, the adsorbed impurities are desorbed and the adsorbent is regenerated at the same time, at least four adsorbent bed cycles are used to operate to achieve a continuous output of product hydrogen.

22000nm ³/h VPSA pressure swing adsorption oxygen generator

Multi-tower combined VPSA pressure swing adsorption oxygen production technology is a new process with low energy consumption, low noise and low maintenance cost. It has been accepted by the first set of devices in Zhejiang Province and is widely used in non-ferrous smelting, glass smelting, iron and steel smelting, chemical industry, paper making and other industries.

SAF Coolest v1.3.1.2 设置面板 QBJSD-ZZZH-FXSVE-DSV

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page