Hydrogen production from natural gas now and in the future

Time:

Mar 08,2022

Research and Development of Hydrogenation Catalyst in Fifteen YearsAbstract: With the development of science and technology at home and abroad, China has made certain achievements in the development of hydrogen production from natural gas, especially in the industry of hydrogen production from natural gas catalyst. At present, some large and medium-sized enterprises in China are mostly introducing foreign technology in hydrogen production from natural gas. Some core technologies such as steam conversion process mainly adopt foreign advanced technology, and some achievements have been made in China. For example, PSA technology developed by a chemical design institute has been applied in the industrial field. And it has its own unique advantages in pressurized steam conversion, its process is relatively mature, and it has been applied in various scales in China.

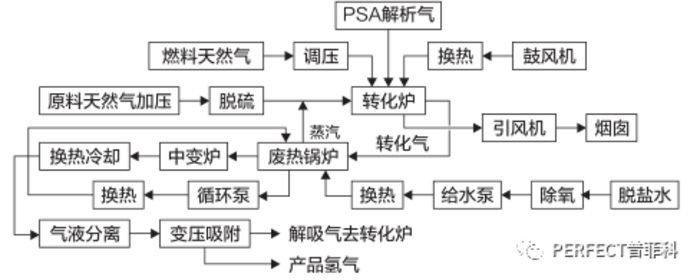

Traditional natural gas hydrogen production process

●The process of hydrogen production from natural gas consists of raw gas treatment, steam conversion,COConversion and hydrogen purification consists of four major units.

(1), raw gas processing unit is mainly natural gas desulfurization, usingMnOandZnODesulfurizing agentH2SandSO2. The processing capacity of the feed gas is large, so when compressing the feed gas, a large centrifugal compressor is selected.

(2), steam conversion unit. Water vapor is used as an oxidant, and hydrocarbons are converted under the action of a nickel catalyst to obtain a converted gas for producing hydrogen. The type and structure of the reformer have their own characteristics, and the structure and thermal compensation methods of the upper and lower gas collecting pipes and the fixing methods of the reformer pipes are also different. Although the convection section heat exchanger is set differently, the process operation parameter setting of high temperature conversion and relatively low water-carbon ratio is adopted in the steam conversion unit, which is conducive to the improvement of the conversion depth, thus saving the consumption of raw materials.

Natural gas hydrogen production reformer

(3)、COTransform unit. The feed gas sent from the converter contains a certain amountCO, the role of the transformation is to makeCOIn the presence of a catalyst, it reacts with water vapor to formCO2andH2. According to the conversion temperature, the conversion process can be divided into high temperature conversion (350~400 ℃) and medium temperature transformation (below300~350℃). In recent years, due to the focus on the conservation of resources, in the conversion unit process settings, began to adopt.COThe two-stage transformation process of high temperature transformation and low temperature transformation is set to reduce the consumption of raw materials.

(4), hydrogen purification unit. Hydrogen production companies have adopted low energy consumption pressure swing adsorption (PSA) The purification and separation system replaces the decarbonization purification system and methanation process with high energy consumption to achieve the goal of energy saving and simplification of the process, and the purity can be obtained at the outlet of the device.99.9%of hydrogen.

Problems of Traditional Hydrogen Production Process from Natural Gas

●There are still some problems in the traditional hydrogen production process, which are mainly manifested in the following aspects:

(1) The economic benefits are relatively poor. The cost of the traditional hydrogen production industry is too high, and the fuel cost is too high. This also directly restricts the progress of natural gas hydrogen production. The economic benefits are poor, and many companies are unwilling to do it.

(2) The waste heat collection and reuse is not high, and the flue outlet temperature is too high during the hydrogen production process, resulting in a lot of heat waste, and the flue gas outlet temperature is still high, wasting a lot of heat.

(3) Hydrogen production requires high-temperature reaction, which requires more expensive equipment, otherwise it cannot meet the demand for hydrogen production, and at the same time requires a large amount of fuel gas, which greatly increases the cost of hydrogen production for enterprises.

(4) Cause a certain amount of pollution, and a large amount of carbon dioxide will remain in the hydrogen production process, which will not only cause waste of resources, but even excessive carbon dioxide will directly affect the environment. Taking high efficiency and low energy consumption has become a major trend in the development of hydrogen production from natural gas. Large-scale equipment and stable process level put forward higher requirements for the factory. At present, China's key equipment in the large-scale converter and its key supporting equipment, large compressors, large-scale.PSAIn terms of equipment and efficient and durable catalysts, there is still a big gap with the international level. In order to narrow this gap, China's hydrogen production companies should develop in the following aspects: first of all, develop corresponding supporting facilities and technological processes; secondly, vigorously develop the level of science and technology to improve the utilization rate of catalysts; again, it is necessary to improve the research level of other precious metals catalysts; finally, increase investment in hardware facilities to better provide public relations for large-scale furnaces and related equipment.

Development Direction of Hydrogen Production Technology from Natural Gas

High temperature cracking hydrogen production technology

●High-temperature cracking of natural gas to produce hydrogen is the catalytic decomposition of natural gas into hydrogen and carbon at high temperature. The process is considered to be a transitional process between fossil fuels and renewable energy because it does not produce carbon dioxide. Liaohe Oilfield has carried out a lot of research work on hydrogen production from high-temperature catalytic cracking of natural gas, and the carbon produced can have specific important uses and broad market prospects.

hydrogen production by autothermal reforming

●This process changes from external heating to internal self-provided heat source, which is more reasonable for energy utilization. This process is mainly that the heat generated by the reaction can be used by other reactions to realize self-heating. The working principle of this technology is to couple some heat in the reactor, which is mainly generated by the combustion reaction of natural gas, and can also react with natural gas water vapor, which can realize the self heating of the reaction. In addition, because the strong exothermic reaction and strong endothermic reaction in the autothermal reforming reactor are carried out step by step, this process still needs some high-end anti-high temperature instruments, which mainly include stainless steel pipes, which also increases the cost of hydrogen production from natural gas and has the disadvantages of low productivity.

Adiabatic conversion technology for hydrogen production

●The adiabatic conversion hydrogen production technology is relatively advanced at present. The biggest feature of this technology is that its reaction raw material is partial oxidation reaction, which can improve the capacity of natural gas hydrogen production device and better control the speed step. The natural gas conversion hydrogen production process mainly uses the air itch source. The designed reactor containing oxygen distributor can solve the hot problem of catalyst bed and the reasonable distribution of energy. The reaction stability of catalytic materials is also greatly improved due to the reduction of hot spots in the bed. The small-scale on-site hydrogen production of natural gas by adiabatic conversion of natural gas can better reflect the characteristics of strong production capacity, and the new process has the advantages of short process and simple operation unit, through this process, the investment cost and hydrogen production cost can be reduced, and the economic benefit of the enterprise can be improved.

Hydrogen Production Technology by Partial Oxidation of Natural Gas

●Compared with the traditional steam reforming method, the energy consumption of natural gas oxidation hydrogen production technology is relatively low, mainly using relatively low refractory stacking reaction, but this process also requires relatively high purity oxygen, which also virtually increases the oxygen production cost and equipment cost. The oxidizer in the catalytic part of natural gas mainly uses high-temperature inorganic ceramics, which can combine cheap oxygen production with hydrogen production.

Value Analysis of Hydrogen Production Process from Natural Gas

●As a chemical product, hydrogen is widely used in reproduction and life, not only in light industry but also in heavy industry. With the development of new energy technology and the enhancement of people's awareness of environmental protection, hydrogen is widely used in production and life, such as medicine, electronics, electrical, fine chemical and other industries. However, the traditional hydrogen production technology has high cost, low production efficiency and some pollution.

Concluding remarks

●About half of the world's hydrogen is produced by natural gas steam reforming process, which is more mature, but with high energy consumption, high production cost and large equipment investment. Therefore, it is of great significance to research and develop cheap new process and new technology of hydrogen production from natural gas. The characteristics of hydrogen market demand in the 21st century will determine the development trend of hydrogen production technology. With the increasingly stringent environmental regulations around the world and the deepening of social concern about clean hydrogen energy, the demand for hydrogen will grow steadily, especially the emergence of fuel cell vehicles, so that the demand for hydrogen has the characteristics of wide distribution and miniaturization. Therefore, we have reason to believe that a variety of hydrogen production methods will develop cooperatively in the world. In areas with abundant power resources, hydrogen production from electrolytic water will develop rapidly, the development of coal gasification hydrogen production technology will slow down, and natural gas steam conversion Hydrogen production will still dominate, and hydrogen production from natural gas catalytic cracking will receive attention due to the rise of fuel cells.

Xunkai Catalytic (SUNCHEM): Fifteen years of focus on the research and development, production and sales of hydrogenation catalysts, positioning to provide users with the most suitable special catalyst products, mainly serving pharmaceuticals, pesticides, dyes, spices, chemicals and other industries. Xunkai's dedicated catalyst products have been used in sorbitol,BDOCaprolactam, fatty alcohol, polyether amine, butyl octanol,HPPOPetroleum resin hydrogenation,RTHydrogenation, dehydrogenation, reductive amination, desulfurization and other processes in the fields of hydrofining. Xunkai is striving to become a representative of high-end catalysts in China's chemical industry and a pioneer in replacing imported catalysts. Xunkai catalyst products include:

RaneCATSeries: Raney metal catalyst series, Raney nickel, Raney copper, Raney cobalt, used for nitro hydrogenation, nitrile hydrogenation.

CuCATSeries: copper zinc, copper silicon, copper aluminum catalyst, used in alcohol dehydrogenation, ester hydrogenation, aldehyde hydrogenation and other fields.

PMCATSeries: Palladium, platinum, ruthenium supported on activated carbon or alumina catalyst, used in hydrogenation, dechlorination, deep desulfurization, fuel cell desulfurization and other fields.

NiCATSeries: Powder supported nickel catalyst, Fixed bed supported nickel catalyst, ApplicationC5resin hydrogenation,C9resin hydrogenation,DCPDResin hydrogenation, rosin and its resins,PAOPolyαOlefins, oil hydrogenation, etc.

More information

SAF Coolest v1.3.1.2 设置面板 QBJSD-ZZZH-FXSVE-DSV

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page